Efficient machining of stator housings for e‑mobility

Newly-developed, patented process for efficient simultaneous machining of stator housings (inner housing) for E‑Mobility

- Semi-finishing up to 8 times faster

- Efficiency increase of up to 100 % compared to conventional turning process

- Compact Machine Mounting due to Vertical Machining

Innovation

-

Serial production solution for efficient ID and OD machining of pot-shaped stator housings by means of a simultaneous turning process

-

Substitution of separate OD turning processes (roughing) by an integrated process of ID and OD machining

-

Significant reduction in machining time

-

Increase in economic efficiency

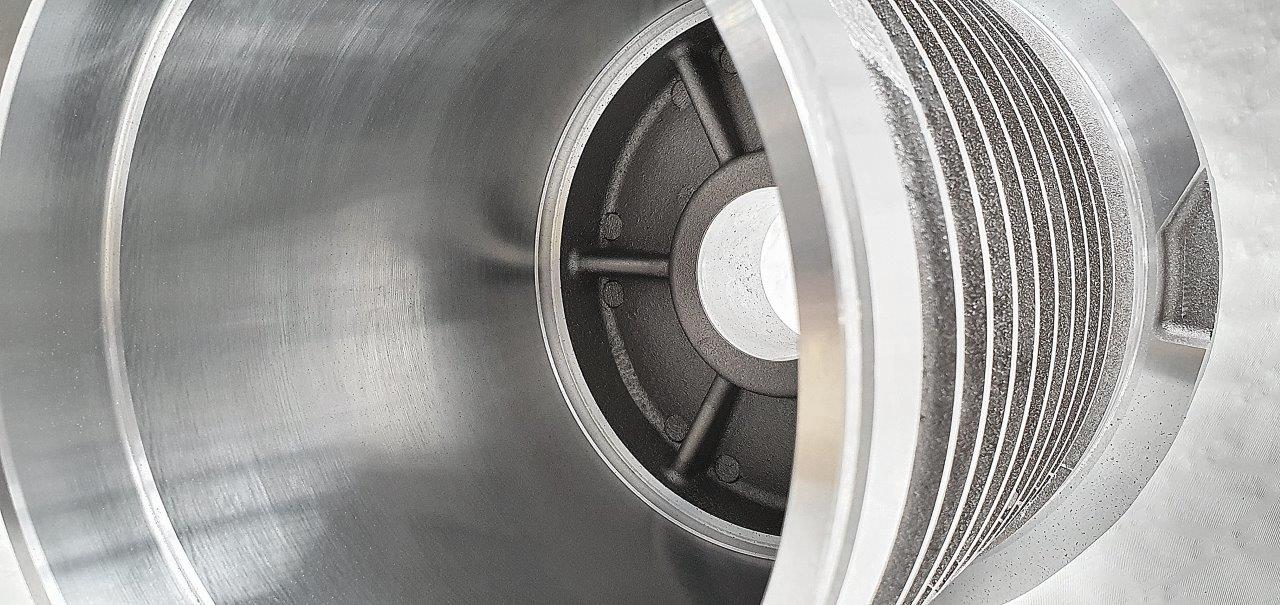

Workpiece

-

Pot-shaped stator housings of e‑mobility with inner and outer contour

-

High requirements for form and position tolerances

-

Fit tolerances IT6

-

Cylinder shapes between 20 and 30 µm

-

-

High requirements for concentricity up to 0.05mm

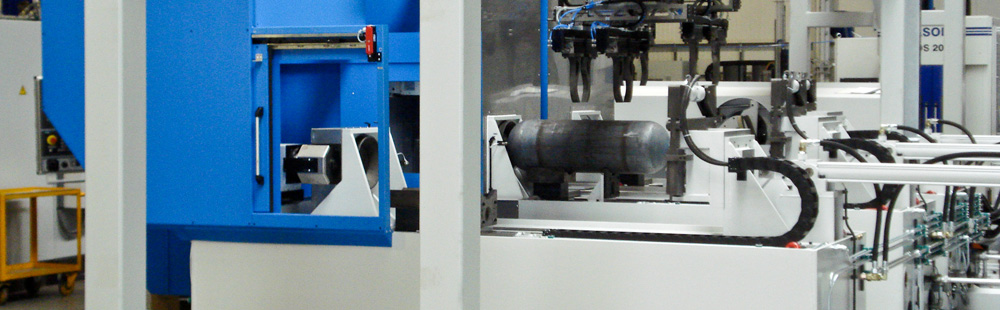

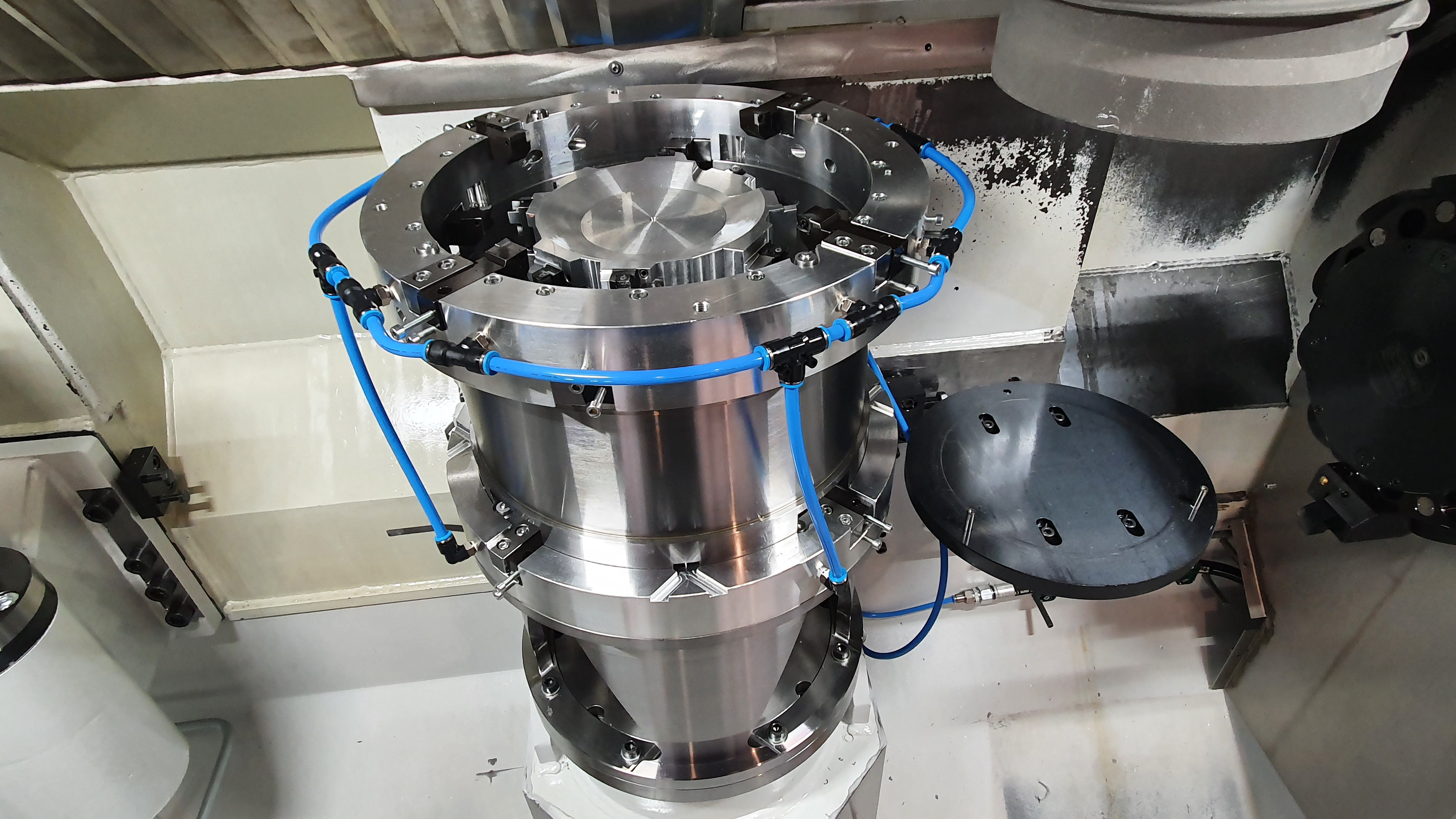

Process Setup

-

Multi-spindle turning center with tool turret

-

Vertical test setup

-

Integration of further machining units through modular design

-

Automatic loading and unloading of workpieces via pick-up

-

Integration of in-process measuring equipment

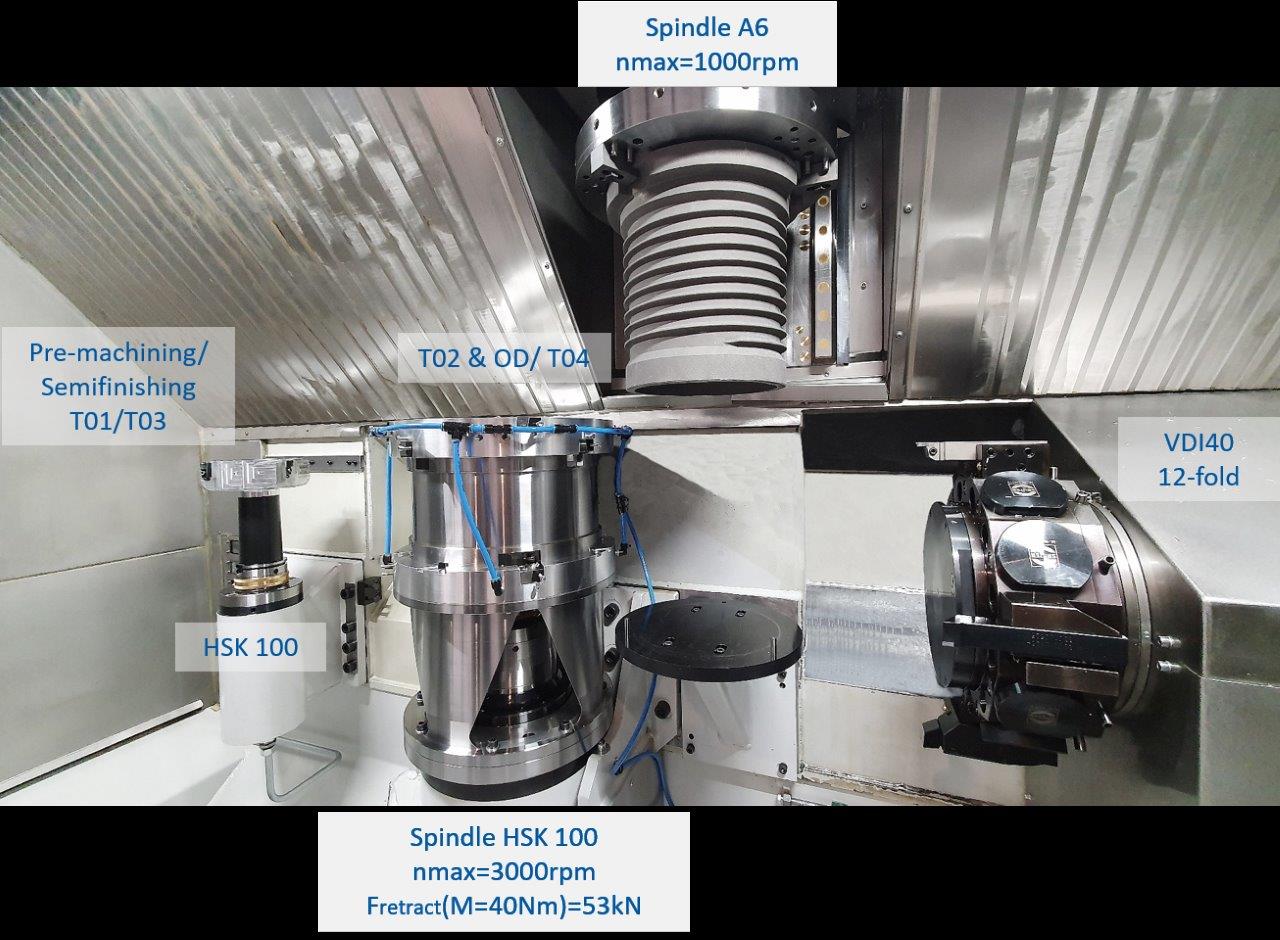

Simultaneously Semi-Finish-Machining

-

Use of special internal boring tools and self-developed external bell tools, which enable machining of the inner and outer contour in parallel

-

Vibration-damped machining on the thin-walled workpiece through simultaneous operation of the inner and outer tools

-

Simultaneous rotary movement of workpiece and inner tool with stationary outer tool

-

Up to 8 times faster machining for the internal and external roughing processes due to simultaneous machining and higher number of cutting edges (4‑fold cutting edges)

-

Lower torque on the clamping device due to counter-rotating cutting forces of internal and external machining (compared to single internal machining)

-

Automated parts handling (pick-up)

-

Reduced re-clamping processes

Benefits

-

Simultaneous ID and OD machining of pot-shaped stator housings

-

Substitution of separate OD machining processes (roughing)

-

Reduction of cycle time: Semi-finishing up to 8 times faster compared to conventional turning processes

-

Less re-clamping operations

- Efficiency increase of up to 100 % compared to conventional turning process

-

Increase in economic efficiency

- Reduction of vibrations in the process

Other Fields of Application

-

E‑mobility stator housings

-

Aluminum castings

-

Heat sinks for hybrid engines

-

Tube-flange couplings for the oil and gas industry

-

Bearing and housing components for general mechanical engineering

-

Workpieces for the plastics industry